Built Different. Built Better.

Every American Marine Sports (AMS) boat is built using our exclusive High-Pressure Injected (HPI) Foam Core Process — a method that goes far beyond standard boatbuilding. It’s not just about what goes into the hull, it’s about what you get out of it: a stronger, quieter, safer boat that lasts longer and keeps its value.

Vacuum-Infused, Kevlar-Reinforced Hulls

At American Marine Sports, every hull is built using vacuum-infusion, a premium composite process that ensures exceptional strength, precision, and long-term durability. Infusion pulls resin through the laminate under controlled vacuum pressure, creating a cleaner, more consistent hull structure than traditional hand-laid methods.

When paired with our advanced composite materials, the result is a hull that is stronger, lighter, and engineered for superior performance.

Full Kevlar Bottom Protection

Across every model we build, the entire hull bottom is reinforced with a full layer of Kevlar. This aramid fiber adds a critical layer of impact resistance—protecting your boat from debris, grounding, and the demanding conditions serious anglers and boaters encounter.

The Advantages You Feel on the Water

- Stronger, more impact-resistant hulls

- Reduced weight for better acceleration and fuel efficiency

- Improved handling and ride quality

- Greater consistency from boat to boat

- Long-lasting structural integrity

Our vacuum-infused, Kevlar-reinforced construction delivers a hull you can trust—built with the same precision and attention to detail you’ll see in the images of our process.

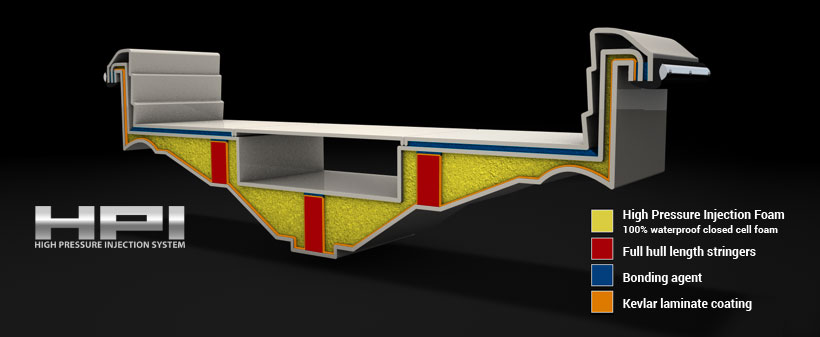

What Makes the AMS HPI Process Unique

Double-Hull Strength

We chemically bond a hand-laminated, vacuum infused, outer hull to a full inner hull. Between them, we inject high-pressure, closed-cell structural flotation foam. This creates a rigid, flex-free foundation you can trust in all conditions.

Noise-Reducing, Ride-Enhancing

The foam-filled core doesn’t just add strength — it also deadens sound and vibration. That means a smoother, quieter ride so you hear the water, not the hull.

Kevlar® Reinforced

Every hull bottom is layered with Dupont Kevlar®, giving you extreme puncture resistance and the confidence to run hard without compromise.

True Safety and Flotation

Our double-hull, foam-filled construction provides built-in flotation, giving you and your family an extra margin of safety if the unexpected ever happens.

Why it Matters to You

Comfort You Can Feel

No rattles, no flex — just a solid ride that inspires confidence.

Showroom Shine That Lasts

Longer mold curing time delivers our signature straight, brilliant gelcoat finish.

Peace of Mind

Extra flotation and Kevlar protection mean you’re prepared for anything.

Long-Term Value

A stronger, more durable hull resists fatigue, water intrusion, and costly repairs — helping your boat hold its value.

The AMS Promise

This proprietary process is more complex, more time-consuming, and more expensive to build. But the payoff is a boat that performs better, lasts longer, and requires fewer repairs. With over 15 years of proven results, we back every AMS hull with a limited lifetime hull warranty.

Because when it comes to your time on the water, we believe peace of mind should come standard.